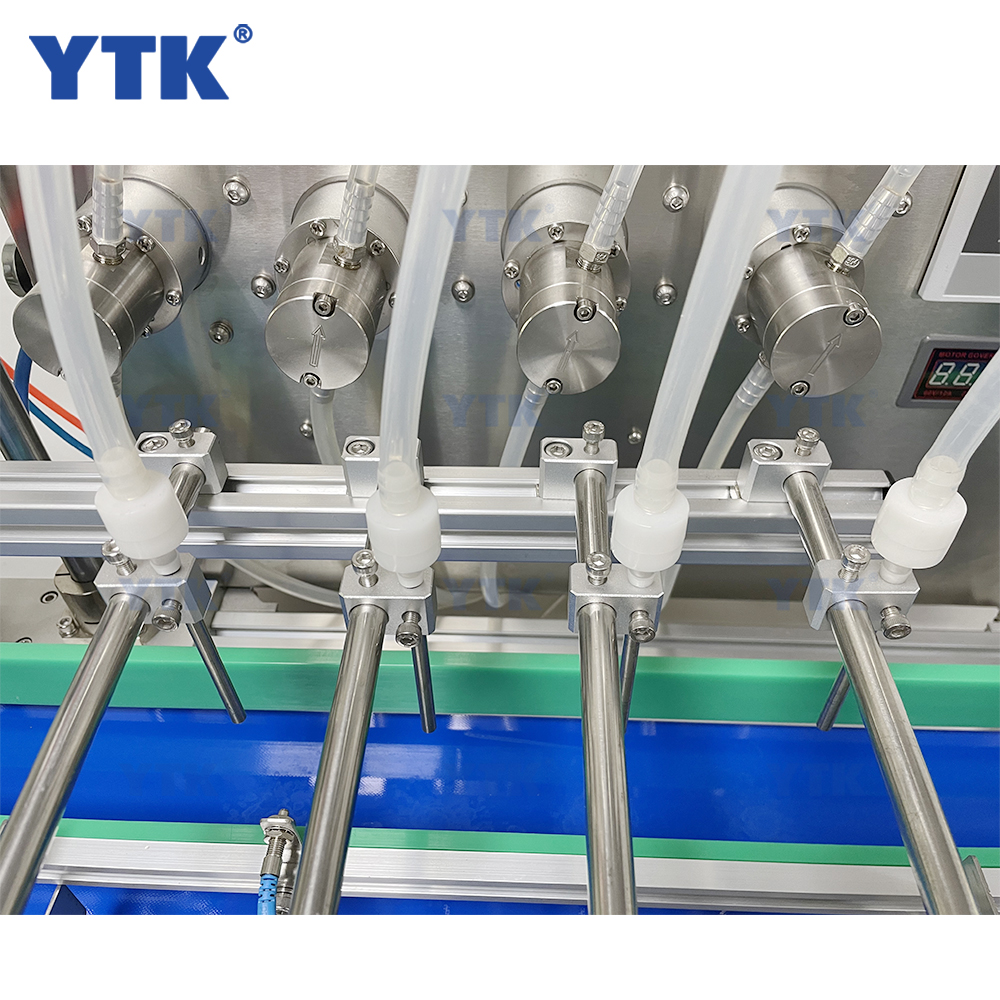

4 Nozzles Magnetic Pump Automatic Desktop Liquid Water Juice Water Filling And Packaging Machine

Description

This magnetic pump’s gear is made of 316 stainless steel, driven by permanent magnet and micro motor.

It features compact size, precision wise and low working noise.

Suitable for Filling various liquid media, such as oil, water, syrup, cleaning agent, organic solvent.

Specification

Machine Size

1112*550*690mm

Machine Weight

50kg

Package Size

1142*590*720mm

Package Volume Weight

98kg

Package Form

Wooden Case

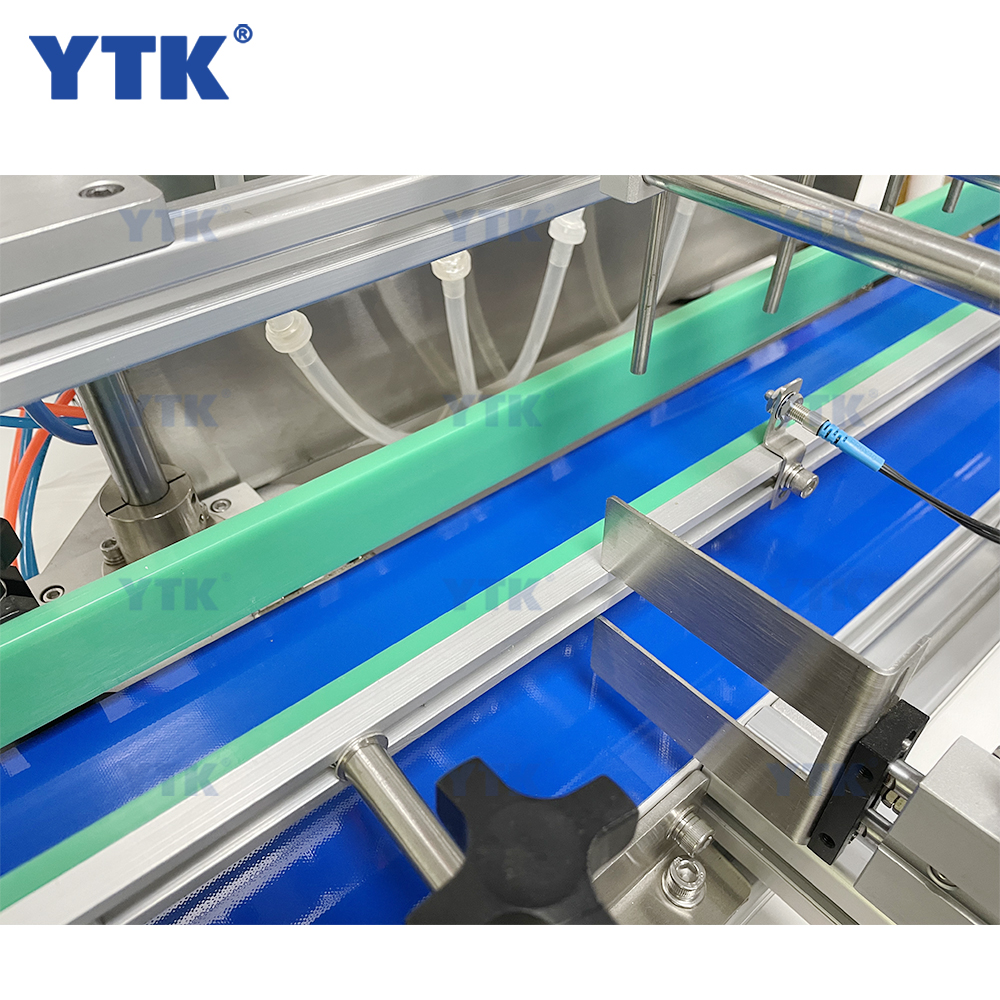

Minimum Bottle Diameter

30mm

Maximum Bottle Diameter

125mm

Minimum Bottle Height

50mm

Maximum Bottle Height

200mm

Nozzle Inner/Outer Diameter

5/6mm

Filling Speed

Four individual speed controller above each pump, you can use them balance the filling speed for all the pumps. Because one pump’s 100% speed may faster than other pump 100% speed, hence you need to lower the speed of this particular one to match against others.

Filling Time

Facing the machine, we number 4 pumps from left to right, you can set different filling time for each one of them, or you can even turn down any one of them.

This setting is used for further more control of the filling volume by set individual filling time at the scale of milliseconds.

Bottles Block Delay

When all 4 bottles are in position, it will start a timer of bottle block delay, when this timer is due, machine will push out the left blocker to lock down these 4 bottles inline.

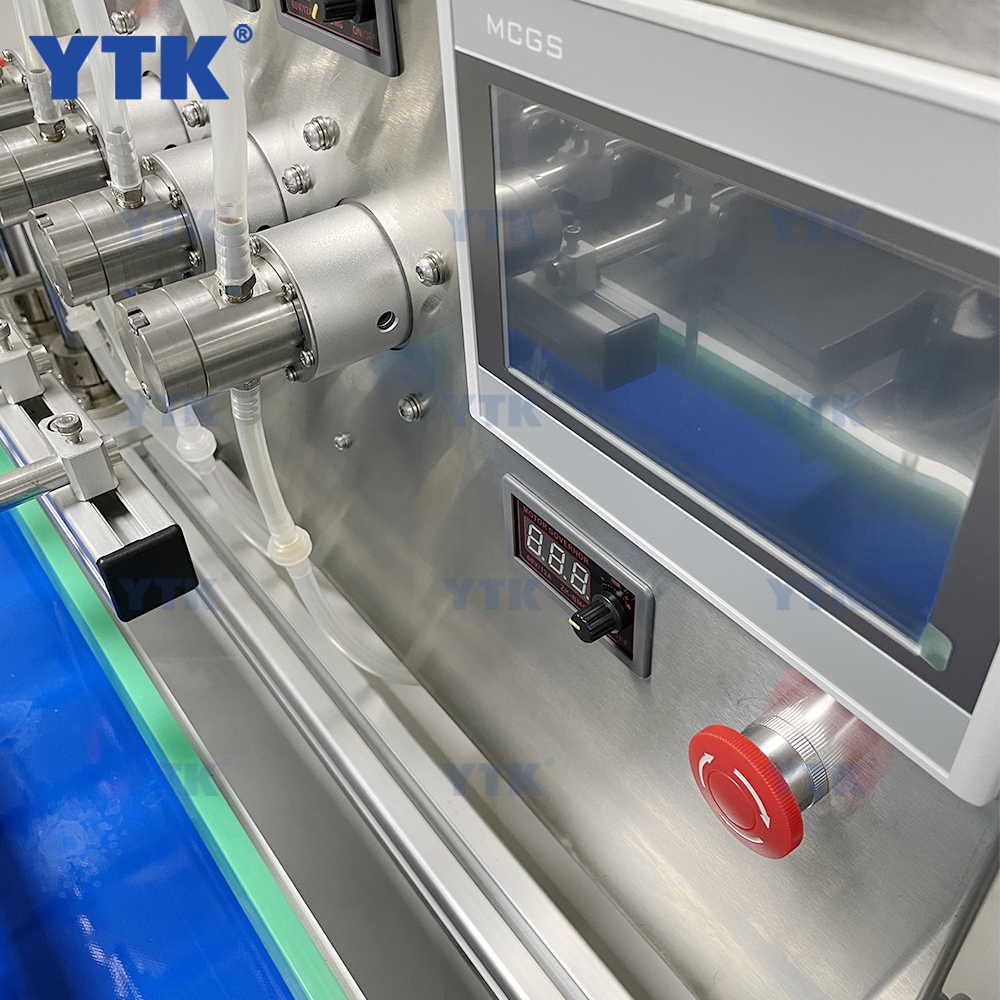

Nozzles Descend Duration

When left blocker is pushed out, nozzles will start to descend, it will take some time for the nozzles to fully descend, this is much related to the air cylinder speed which you can adjusted by the valves on the cylinder.

Nozzles Retain Duration

When the descend duration is due, nozzles will start filling, also machine will start counting of this retain duration to retain the nozzles position at lowest level. You should notice that this retain duration is always shorter than your filling time, otherwise the whole filling process is not that efficient.

Nozzles Ascend Duration

When the retain duration is due, nozzles will start to retract, set a proper time duration for this process can improve efficiency of whole filling process.

This is changed based on the retracting speed adjusted by the valves at bottom of the air cylinder.

Our four heads desktop automatic liquid filling machine is very efficient with high cost performance. It is widely used in medicine, daily chemical and other industries such as essential oils, perfumes, juice liquid etc. Machine with magnetic pump is good choice for low viscous corr, a little foamy liquid. 316 stainless steel pump can use for very high temperature liquid fill.

It is suitable for various corrosive,low viscosity and non-particulate liquids, such as:various chemicals (medicine oil, medicinal liquor, alcohol, eye drops, syrup), chemicals(solvent, acetone), oil (edible oil, essential oil) ), cosmetics (toner, makeup remover,spray), food (100 degree high temperature, such as milk, soy milk), beverage (juice, fruit wine), seasoning (soy sauce vinegar) and other non-particulate liquid; high and low foam liquid ( Care solution, detergent)

Name: Doris Dai

Mobile:008618070291575

Tel:008618070291575

Email:cnpacking@outlook.com

Add:No.2 Xinggong Road, Gangtou Industrial Zone, Wenxi Town, Qingtian County, Lishui City, Zhejiang Province