1) The stainless steel structure is used for the key parts of the machinery, which meets the sanitary requirements for food QS (production license) and pharmaceutical GMP (pharmaceutical packaging)

2) Double frequency control, the bag length is set and cut, saving time and film

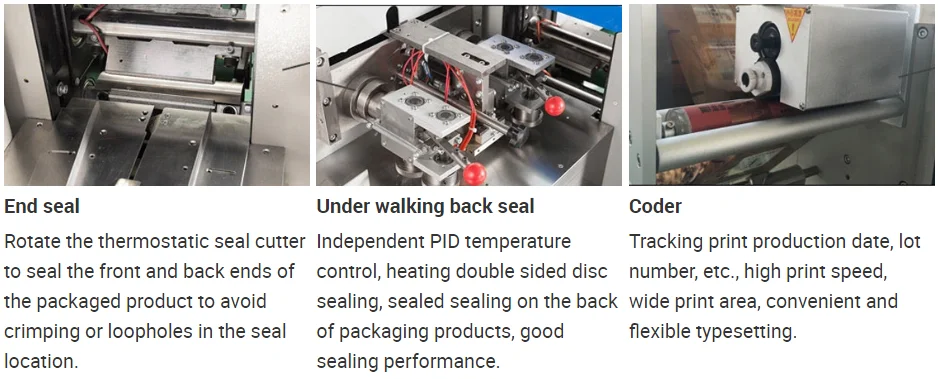

3) High-sensitivity electro-optical eye tracking, no manual adjustment after setting, sealing and cutting size, accurate position, and firm and beautiful sealing

4) Temperature independent temperature controller: intelligent control, stable temperature control, better suitable for all kinds of packaging materials;

5) Color touch screen display; positioning stop, fault automatic diagnosis function, display, at a glance;

6) Automatic production counting, quantitative production, and packaging production accuracy;

7) Mechanical design and transmission system is simple, work is more reliable, and maintenance is more convenient