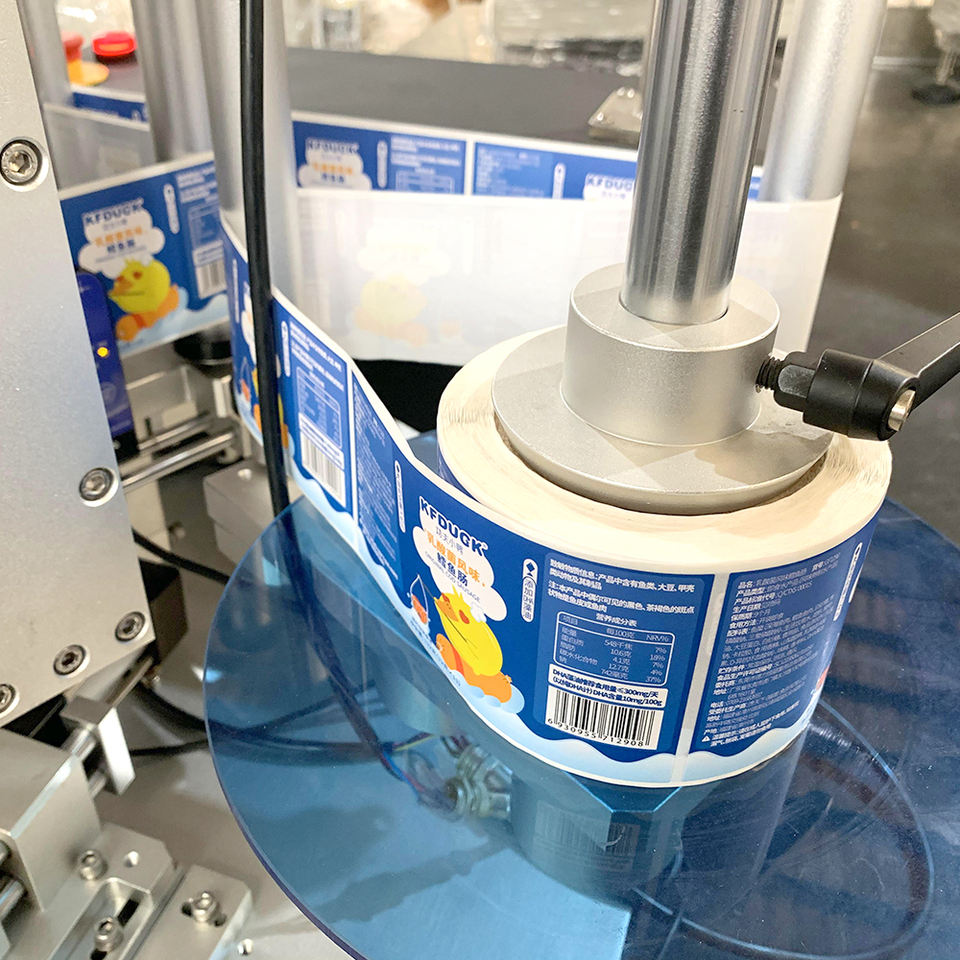

1. is powerful, single and double labeling functions can be switched at any will, the distance between the back double labels can be flexibly adjusted, optional circular positioning function, the position labeling is set on the circular surface; 2. supports tapered bottle stickers, with a tapered adjustment knob, simple adjustment can meet the tapered bottle stickers; 3. labeling quality is good, with the dual positioning of product positioning, label correction, label head and tail docking overlap degree, no folds, no bubbles, improve the guarantee quality; 4. adjustment is simple, all kinds of functions one-key switch, different product label label switch is simple and fast, improve efficiency; 5. safety and hygiene, in line with GMP production requirements, the main materials of stainless steel and advanced aluminum alloy, durable; 6. performance is stable, using PLC + fiber sensor electric control system to support long operation of equipment;

7. production management is convenient, with standard count, power saving mode, photoelectric tracking label and other functions, production management is easier;

Name: Doris Dai

Mobile:008618070291575

Tel:008618070291575

Email:cnpacking@outlook.com

Add:No.2 Xinggong Road, Gangtou Industrial Zone, Wenxi Town, Qingtian County, Lishui City, Zhejiang Province